inspection

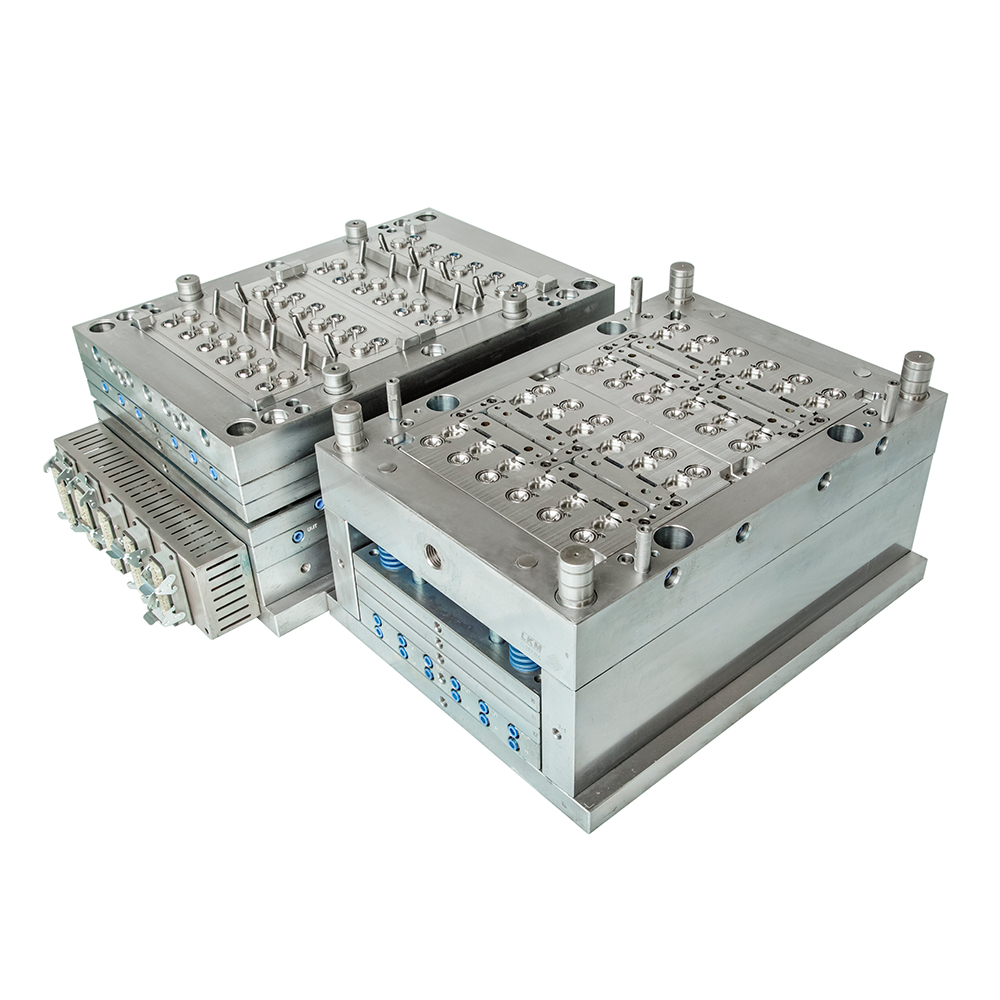

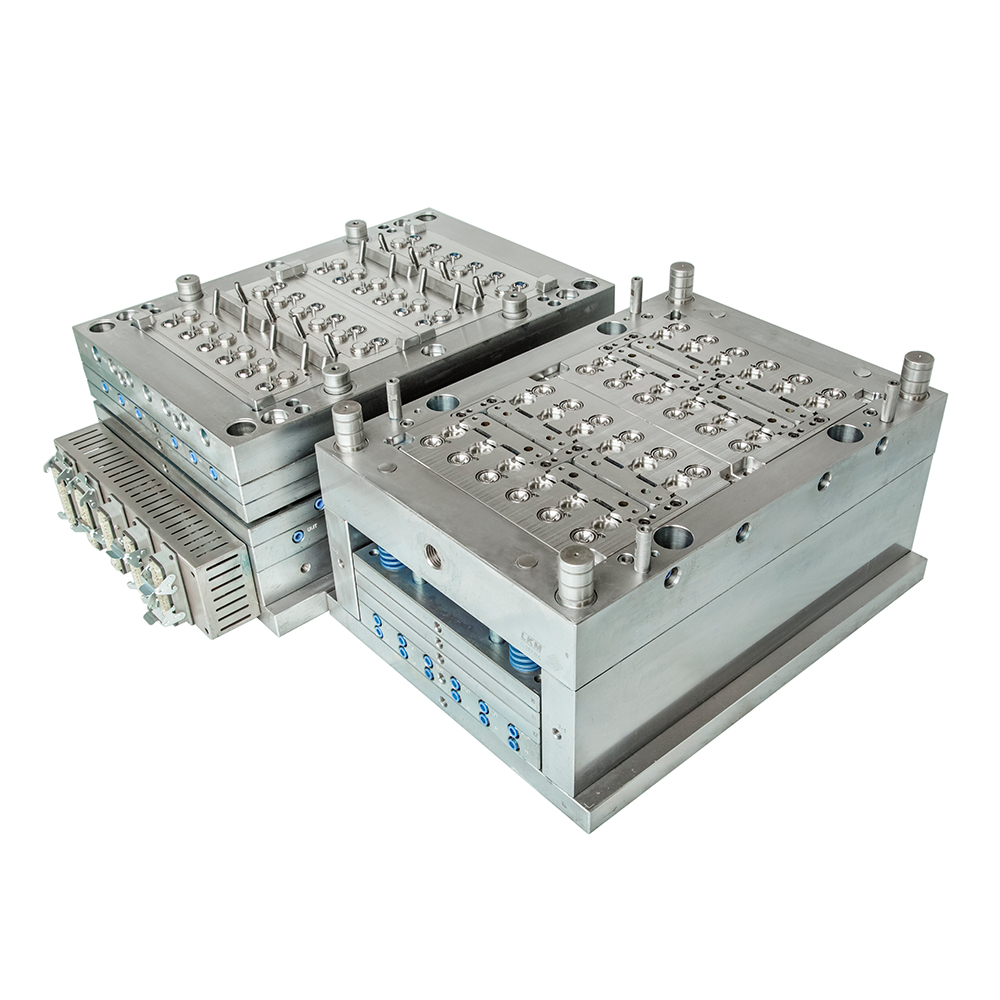

After the externally processed molds are returned to the company, the custodian of the logistics department will make a temporary receipt (the mold must have a name and drawing number identification, and it will be rejected without identification). Outsourced members fill in the inspection form and submit it to the Quality Department. After receiving the inspection application form, the quality department fills in the internal commission form and informs the workshop to cooperate with the inspection (disassembly and assembly of molds).

The molds manufactured within the company shall be submitted to the quality department for inspection by filling out the inspection form in the mold manufacturing workshop.

initial inspection

1 Check the structure and appearance of the mold.

2 Check the dimensions of the mold, focusing on the dimensions of the formed parts and the dimensions of the installation.

3 Check the surface roughness of each component.

4 Check the material and heat treatment of each key component of the mold.

5 Check whether the mold accessories are complete.

6 After the mold inspection, the quality inspector will hand over the mold acceptance form to the outsourcing partner (outsourcing mold) or the mold manufacturing workshop. For the molds that pass the initial inspection, after receiving the mold acceptance form, the outsourcer (outsourced mold) or the mold manufacturing workshop will fill in the internal committee form for mold testing and submit it to the technical department. The technical department will submit the mold trial internal order and mold acceptance form to the mold use workshop to arrange the mold trial. (Mold testing is led by the technical department, and the production department sends people to assist the technical department in mold testing.) New mold testing is included in the production plan.

7. For the molds that fail the initial inspection, the mold manufacturing workshop will rework them until they pass the inspection; for outsourced molds, the outsourcer will notify the supplier to rework them until they pass the inspection.

Test mold, nuclear sample

1 The mold trial should be undertaken by experienced and skilled operators or technicians.

2 Before mold testing, carefully digest product drawings and technical requirements, understand the raw materials used, product shape, size and volume (weight), etc.

3 Understand the mold structure, design intent and equipment used, consider issues such as mold loading, feeding, and demoulding, and formulate a temporary mold trial process.

4 After the mold is installed, open and close the mold several times repeatedly to check whether the movable parts of the mold are flexible and free.

5 During the mold test, the mold test records should be carefully made, and the process parameters should be adjusted continuously until the self-inspected products are produced, and then the samples should be sent to the quality inspector for a comprehensive inspection. The quality inspector should carefully fill in the product inspection results (including size, appearance, etc.) on the mold acceptance form.