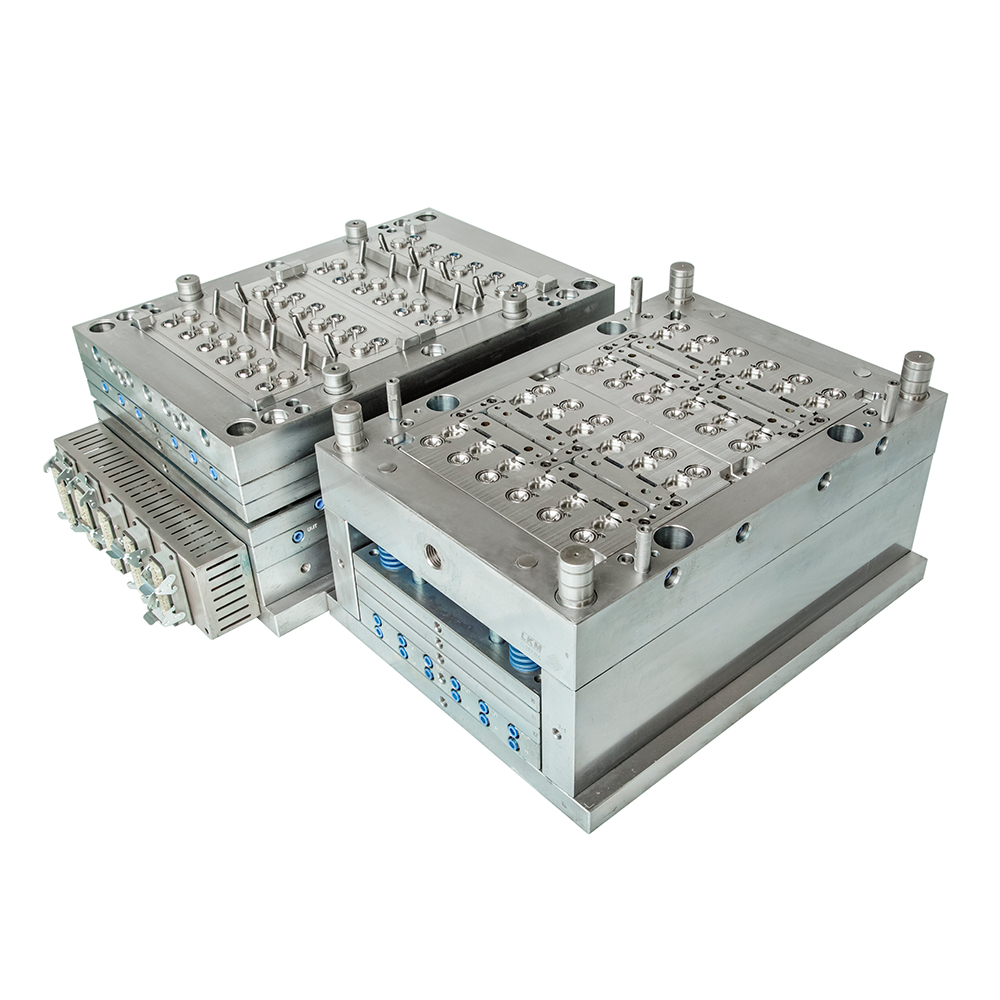

Custom preform moulds offer a range of benefits when it comes to precision and efficiency in various manufacturing processes. These moulds are specifically designed to meet the unique requirements of a particular product or production line. Here are some of the key benefits of using custom preform moulds:

Precise Product Specifications: Custom preform moulds are tailored to the exact specifications of the product being manufactured. This level of precision ensures that each preform produced is consistent in size, shape, and quality. It helps maintain product integrity and reduces the risk of defects or variations.

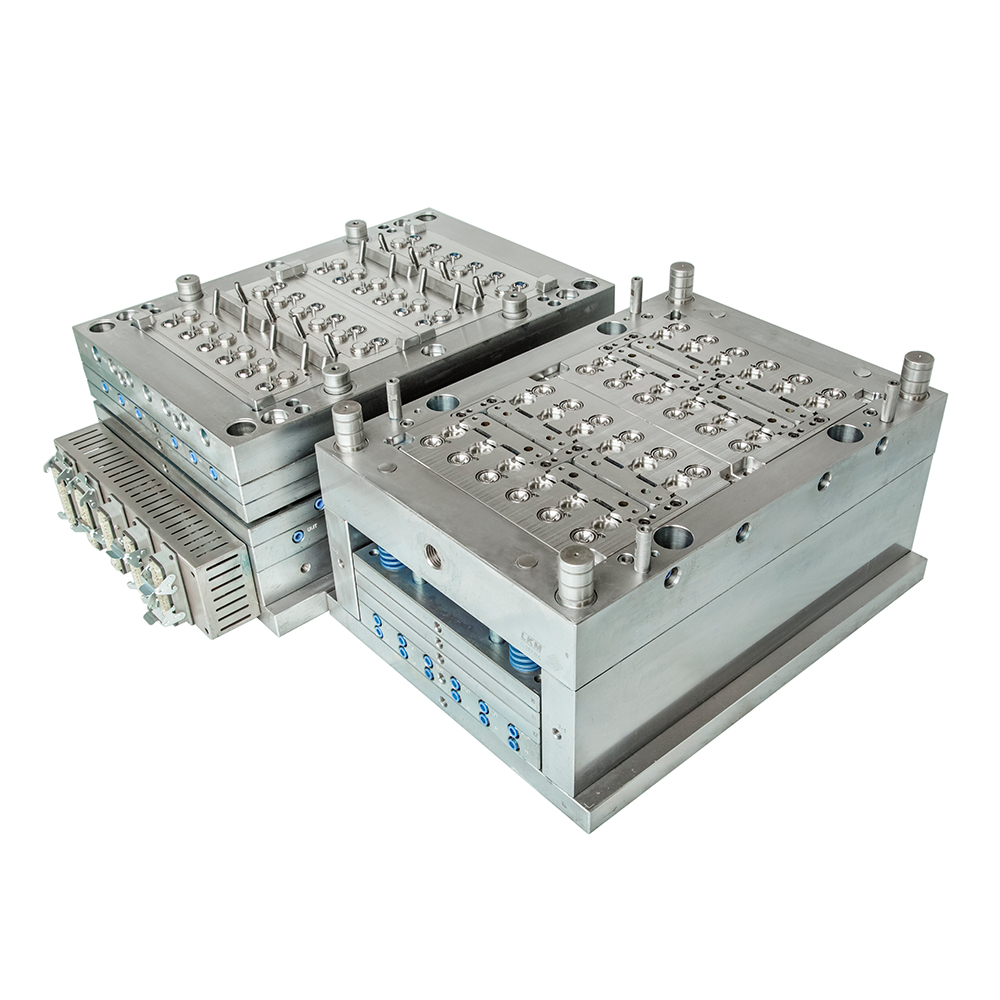

Improved Efficiency: Custom preform moulds are designed with efficiency in mind. They are engineered to optimize material usage, reduce cycle times, and streamline the manufacturing process. By maximizing production efficiency, manufacturers can increase output and reduce costs.

Enhanced Product Performance: The use of custom preform moulds allows for the optimization of product performance. mould design can be adjusted to meet specific requirements, such as wall thickness, strength, or flexibility. This ensures that the final product meets or exceeds performance expectations.

Cost Savings: Custom preform moulds can contribute to cost savings in multiple ways. By minimizing material waste and reducing the need for rework or rejects, manufacturers can reduce production costs. Additionally, the efficiency gained through custom mould design can lead to higher production volumes and economies of scale.

Faster Time to Market: Custom preform moulds can help accelerate the product development and manufacturing process. By working closely with mould designers, manufacturers can ensure a faster turnaround time from concept to production. This allows for quicker market entry and the ability to meet tight deadlines.

Flexibility and Adaptability: Custom preform moulds offer flexibility and adaptability to changing production needs. Manufacturers can easily modify or reconfigure the moulds to accommodate design changes, production scale-ups, or new product variations. This adaptability helps keep production lines versatile and responsive to market demands.

Quality Control: Custom preform moulds enable manufacturers to have greater control over the quality of their products. The precise design and manufacturing process ensure consistent and reliable results. Manufacturers can implement strict quality control measures and monitor the production process more effectively.

Brand Differentiation: Custom preform moulds allow manufacturers to create unique and distinctive products. By customizing the shape, design, or branding elements of the preforms, companies can differentiate themselves in the market and enhance brand recognition.

It's important to work with experienced mould designers and manufacturers when opting for custom preform moulds. They will have the expertise to design and fabricate moulds that meet your specific requirements and ensure optimal performance.

In summary, custom preform moulds offer precise product specifications, improved efficiency, enhanced performance, cost savings, faster time to market, flexibility, quality control, and brand differentiation. These benefits make them an attractive option for manufacturers seeking to optimize their production processes and deliver high-quality products.

English

English 中文简体

中文简体 Español

Español