Test tube molds are used to create test tubes of various sizes and shapes. These molds are typically made of high-quality materials such as stainless steel, aluminum, or plastic and are designed to withstand high temperatures and pressure.

Here is a comprehensive guide that covers everything you need to know about test tube molds:

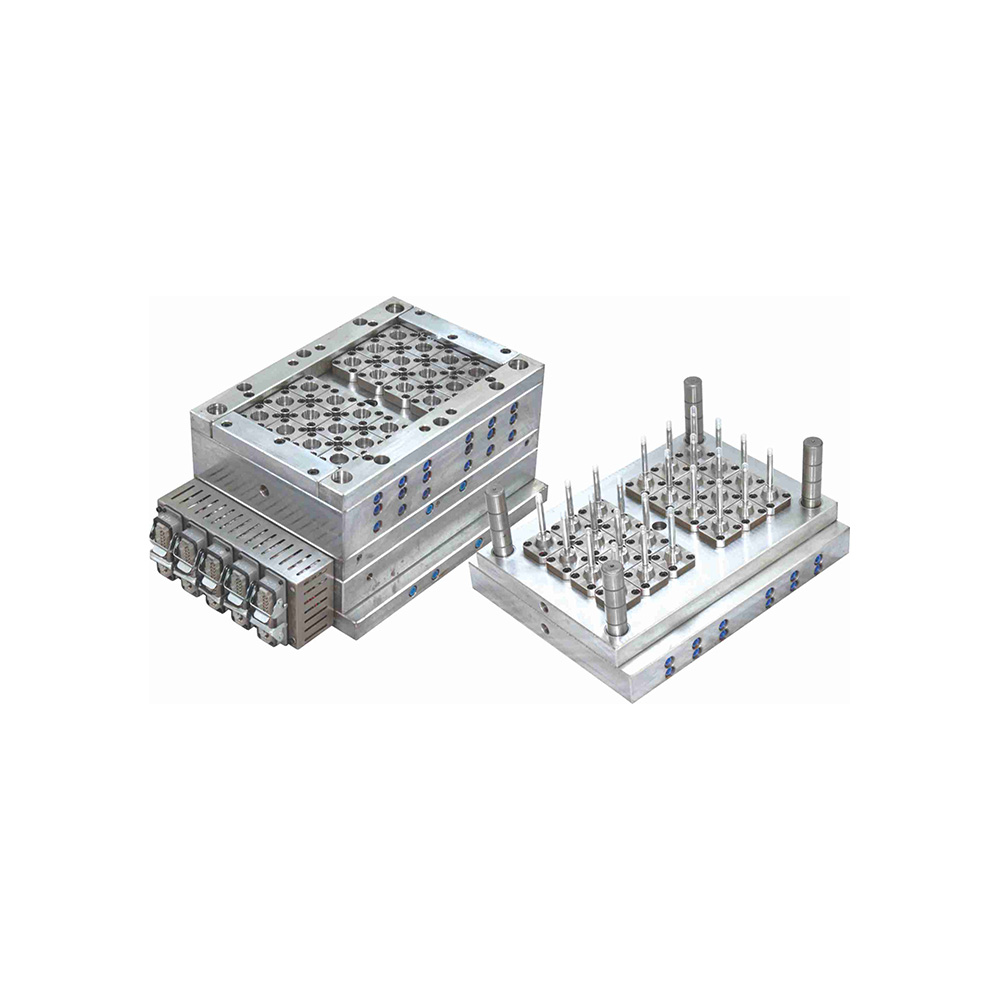

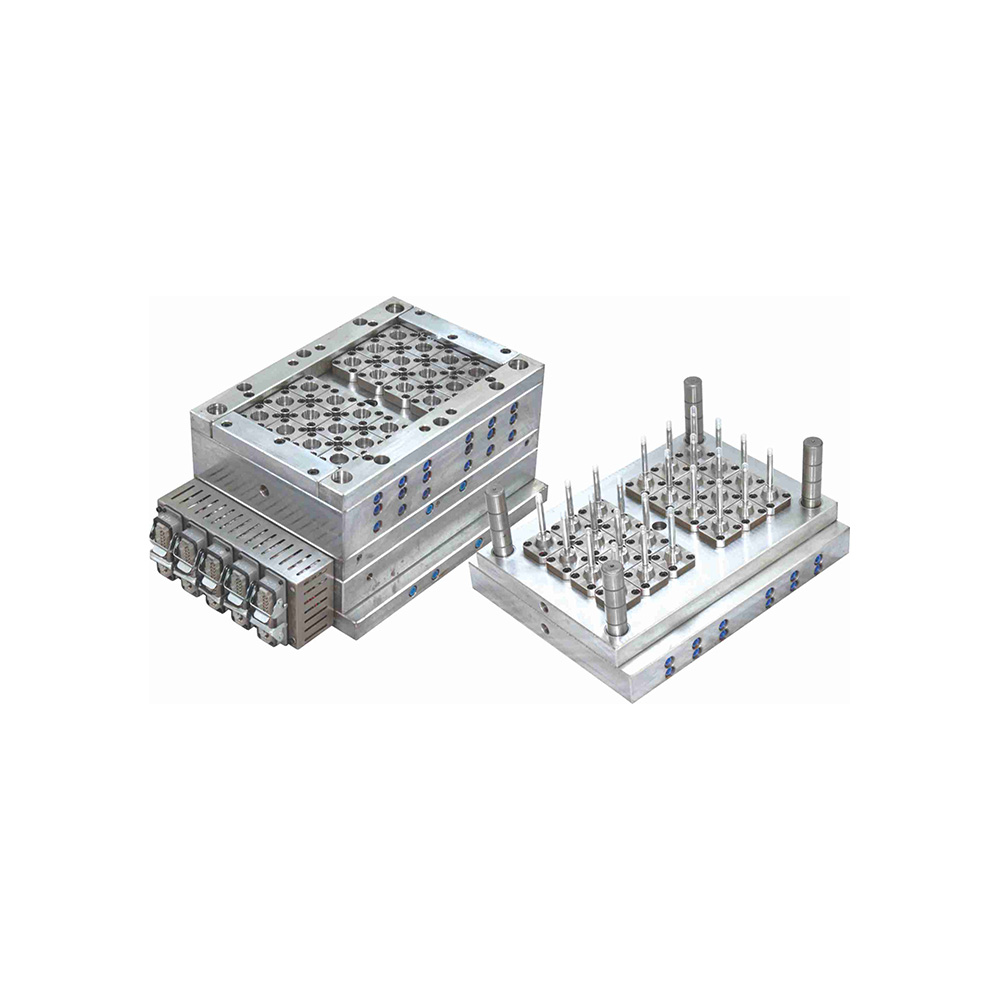

Types of Test Tube Molds: There are several types of test tube molds available, including single-cavity molds, multi-cavity molds, and adjustable molds. Single-cavity molds create one test tube at a time, while multi-cavity molds can create multiple test tubes simultaneously. Adjustable molds can create test tubes of various sizes and shapes. Common types include round-bottom molds for standard test tubes, conical molds for centrifuge tubes, and specialty molds for specific applications.

Materials: Test tube molds are typically made of high-quality materials that can withstand high temperatures and pressure. Stainless steel and aluminum are popular choices for molds that will be used in high-temperature applications. Plastic molds are also available for lower-temperature applications.

Production Process: Test tube molds are typically produced using a molding process that involves heating and molding the material into the desired shape. The mold is then cooled and removed from the mold, resulting in a finished test tube.

Applications: Test tube molds are used for a range of scientific and laboratory applications, including chemical testing, medical research, and microbiology. They can be used to create test tubes for samples, chemicals, or other materials that need to be contained and analyzed.

Sizes and Shapes: Test tube molds are available in a variety of sizes and shapes, from small, round test tubes to larger, rectangular tubes. The size and shape of the mold will depend on the specific needs of the user and the type of test tubes being created.

Molding Process: Test tube molds are typically produced using a molding process that involves heating and molding the material into the desired shape. The mold is then cooled and removed from the mold, resulting in a finished test tube. The molding process involves heating the raw material (e.g., glass or plastic) and shaping it using the test tube mold. For glass test tubes, the molten glass is poured into the mold and then cooled to solidify into the desired shape. Plastic test tubes can be formed through injection molding or blow molding processes.

Care and Maintenance: To ensure the longevity of the mold, Test tube molds should be cleaned thoroughly after each use to remove any residue or contaminants. Regular inspection for damage, such as cracks or warping, is essential. Follow the manufacturer's guidelines for proper maintenance and storage.

Safety: When using test tube molds, it is important to follow proper safety procedures to prevent injury. This includes wearing appropriate personal protective equipment, such as gloves and goggles, and ensuring that the mold is used in a safe and controlled environment.

Quality Control: Quality control measures, such as regular calibration and inspection, should be implemented to ensure the accuracy and reliability of the produced test tubes. This helps maintain consistency and prevents defects or deviations in size and shape.

In conclusion, test tube molds are an essential tool for creating test tubes of various sizes and shapes. Always refer to the manufacturer's documentation and follow laboratory protocols for optimal performance and safety.

English

English 中文简体

中文简体 Español

Español